FLASH DRYING TECHNOLOGY- An Investors Extraordinary Journey With The New Technology In Uganda

For a long time, farmers engaged in cassava processing in the Lango region had faced burdens of processing cassava during the rainy seasons. The bad weather during this season always affected the quality of the cassava flour.

For a long time, farmers engaged in cassava processing in the Lango region had faced burdens of processing cassava during the rainy seasons. The bad weather during this season always affected the quality of the cassava flour.

Chipped or grated cassava would take longer to dry and would be highly contaminated by extraneous materials. Introduced from Nigeria in 2016, the flash dryer, a high precision indoor modern cassava drying technology, came at an opportune time.

The technology, makes processing independent of weather, so processors can dry their cassava throughout the year irrespective of weather. This sent many processors smiling after an upgrade from open air processing to the new technology that offers the best answer to weather challenges especially during the wet seasons.

The flash dryer is a state of the art machine designed to dry wet cassava mash, extracted from the cassava graters, into High Quality Cassava Flour (HQCF) within 3 seconds, making it ready for human and commercial use. The flash dryer can process 3 to 7 tons of HQCF per day.

This technology was introduced by the CAVA project in 2016. Two potential investors from Northern Uganda; Wind Wood Millers Limited in Lira municipality and Adyaka Wholesalers Limited in Apac district picked interest in the multi-million-dollar investment after partaking in a study trip to Malawi to witness the machine at work.

They were amazed at the entire process and decided to come back home and adopt the technology after realizing the benefits including the potential to create employment for more than 2,000 smallholder farmers working as out growers supplying fresh cassava roots to the factories.

Mr. Ivan Okori, Managing Director, WindWood Millers Ltd

Ivan Okori, the Director, Windwood Millers Limited Cassava factory speaks to local Tv and radio press on the profitability of the flash drying technology and the benefits of the technology to the communities in Lira district and beyond.

Ivan Okori, 32 years, is a young shrewd down to earth business man from Kole district, Northern Uganda. He is the Managing Director of Windwood Millers Limited (WML) cassava factory. Ivan has been in the cassava business for close to 10 years. However, his journey with cassava begun way back because for as long as he can remember, cassava has been a very big part of his life.

“I grew up seeing cassava, surviving off it and understanding the potential of what it offered meant for my community and region”

“If every member of the community owns at least an acre of cassava and earns about 1000 USD per season, it would mean a lot for the development of the community. Children would be able to attain a good education, there would be food security and improved nutrition due to the proceeds and also the fact that cassava has the necessary shock-proofing compared to other crops that are susceptible to drought.” says Ivan.

The story of Wind Wood Millers Ltd cassava factory

Wind Wood Millers Limited was incorporated on August 2011 in Lira district, Northern Uganda. Initially, the company dealt with rice production until 2013 when it embraced cassava. During this time, CAVA had already engaged with the company and extended the project outreach programmes to develop the factory to venture into High Quality Cassava Flour (HQCF) processing.

“By this time, I had seen the potential of cassava growing so fast, and I was among the first people that worked with Uganda breweries limited (UBL), a beer company that needed cassava to brew their popular Ngule and Senator beer brands. So, I started aggregating and sourcing for them this raw material. CAVA had been aware of our push towards cassava and were interested in finding flexible businesses that had high potential for growth as SMEs in areas the project targeted. And from that we had initial contact and engaged in discussions to jointly tread the journey.

And so, we walked with them through the journey of working with farmer groups, having these tested, analyzing them and meeting the potential markets. We have been with them through the whole journey to this day of us having the flash dryer. We worked with mainly 17 farmer groups from Eastern and Northern Uganda through the CAVA Project that reached out to farmers and extended skills in good agricultural practices, trained them in using new processing technologies and also availed these technologies to the farmers, especially the use of raised metallic drying technologies to obtain a quality product ready for the market.

These farmers were trained to hygienically handle and dry the cassava at the right time so that its potential qualities like the starch remain intact. CAVA set a precedent away from the traditional ways/ methods of placing it directly on the floor which highly compromised quality and these interventions greatly revamped the cassava value chain.

My work as an aggregator was made easy. I sourced for quality chips from the farmers who were by this time organized into farmer groups. After I got the chips from the farmers, I milled this into flour and supplied to the brewery but also the local markets especially the composite flour millers and bakeries. The product was to the standards expected by the markets- very good quality.” Ivan adds that since the interventions, the crops potential has widened. “Today, cassava price has doubled more to what it was that time.

In some uses, it has twice doubled and I think the potential is even greater if we follow through what other countries are doing with it, for example, Thailand and other western countries that have maximally used cassava way down to glue making, glucose /fructose production, and other industrial applications. Every month am surprised by what comes up. I have seen that cassava can do paperboard and so far, the trials to apply it have been quite successful and that is a market we are working to tap into.

I have also recently got to learn that cassava can be used to make a certain type of cement. This is amazing. And, with all these developments, I see cassava as a crop of the future and am also glad that Wind Wood Millers is at the fore front of pushing to ensure that the cassava future is bright not just for us or the communities we work for but also beyond.” remarks a smiling Ivan.

Ivan says that the factory is located in the area because it is known to be a cassava basin and this favors its presence there.

Mr. Okori, the Director, Windwood Millers Limited Cassava factory (left) and employees, process fresh cassava root into High Quality Cassava Flour (HQCF) using the flash drying technology.

His journey to acquiring the technology

In 2015, Ivan was selected and facilitated by the CAVA project to visit Malawi to experience and witness first-hand the flash drying technology. And just like Mr. Sam Opio of Adyaka Whole Salers cassava factory, he too acquired the investment that CAVA supported him to obtain. Today, he and Opio are the only two investors of the now fully operational cassava factories in Lira and Apac districts, in Northern Uganda.

He passionately speaks of how he was inspired to take on the investment. “When in Malawi, I had quite some interesting experiences from which I learnt a lot. I interacted with a young gentleman not more than 4 years older than me who had a 400acre cassava farm.

I had never in my life seen so much cassava, funny, because you would think growing up seeing cassava gardens all around me, I had seen all the cassava there needs to be seen, but NO! apparently, I had not. This, to me was an interesting challenge and was the initial spark / drive to scale up my gardens.

Then I saw the cassava factory in operation and was quite amazed at how the HQCF was produced in just seconds, and the same product was being used to make biscuits. This also blew me away.

I really liked the consistency with which they were able to buy/use fresh cassava root, process it, dry it, pack it and take it to the production site of the biscuit company and produce an end product ready for the market.

This all got me seriously thinking, ‘if they could do it, so can I’. And when I returned, my mind was already sold into it all. And the reason I was quick to take up this technology was due to the consistency in production quantity and quality of the end product.” says a cheery Ivan.

Challenges with acquisition of the Flash dryer

Ivan narrates the struggles he endured with acquiring the multi-million-dollar investment.

“This was quite a tough journey. First of all, the model was from Nigeria and so had to be shipped here. Also, all through the process, we were very much convinced that the agro processing machinery was tax exempt and so, our financial base at the time the dryer was coming in was mainly focused on just setting up the factory housing structure based on the designs availed by the NOBEX Technologies engineering team from Nigeria.

But, when the machinery came, we were shocked to discover it was not tax exempt. This was a blow that cost us about 17,000USD. It was a tough battle that took about 6 months and we lost quite some money in it. Tuning the machines took a very long time of close to about 2 years and the greatest challenge post installation has been the cost of fuel to run the machinery.”

He also mentions that to address this, there are approaches being applied by the company to tackle the fuel challenges. “We first of all are working to retune the machines to use less fuel. We conducted a market study for the different clients, understood what they require and are giving them exactly that. We segmented our product lines and are creating different variety products of very high grade, middle and more affordable grades.

All these efforts are so that we cut fuel consumption by over 50%.” The factory is currently producing different grades of quality flour to satisfy the different target markets.

Ivan feels there is a huge lesson to learn from the entire experience. “The lesson around this is that if we were to do it again, we would be best prepared on how to handle this especially seeking prior exemption before the machines are on their destination from the original countries.”

Challenges in the flash drying business thus far

He narrates the challenges in the business. “Sometimes there is scarcity of cassava root and this causes a hike in buying price. We are also not yet certified which is keeping us out of penetrating the international markets, and these are many because they have a high utilization capacity for the cassava flour since it is gluten free.” Ivan also mentions that they are still faced with challenges in marketing the HQCF product because there is still little knowledge on its potential use and application in different industries.

He also points out that there is still need to replicate the model to a more affordable and less man power intensive enterprise. “Given that there are different stages in the flash drying process, this somewhat slows down the drying process and we feel that we are not utilizing it to its fullest capacity. Along the way, there is peeling and we currently use peelers but the job is still not a hundred percent. This can greatly affect the end product. Aside from that, the cassava needed is a lot and the processes are tedious, because there is peeling, washing, pressing, and to be honest, if these were automated, it would save us a lot more money.”

Benefits of the technology

Ivan, despite the struggles, confesses that the investment is one of the best decisions he has made in life for he sees a bright future ahead. “The market for HQCF is quite big and we are tirelessly working hard to hit this market. The companies I supply to are very impressed with my HQCF and I look forward to a long working relationship with these because they have appreciated how using local raw material like cassava flour has greatly contributed to cutting down on their costs of production. For example, they attest that the product has impacted on their industry targets because they save about 400 UGX per kilogram purchased. These save between 5000 to 8000 USD monthly by buying our flour.”

He further notes that the investment has enabled them create high level products that are able to meet the different industry demands with quality and consistency. This has informed the company to come up with the right price for the different target industries. “By using the technology, we are able to measure improvements in productivity, thus enabling us save time and costs. There is a huge efficiency saving in using the dryer and it’s a whole different production process which is less tedious than having to depend on weather. With this, we are assured of a consistent quality product that leaves a client happy and satisfied.”

He also attests that the investment has landed him more partnerships and elevated his stature as an SME in the Lango sub region. “We have secured more markets stretching to as far as South Sudan due to a strong network created over the years. WML has a pool of farmers that have reached out to us for planting material and this offers a basic drive to develop our communities. We also have a pool of companies, NGOs, Government initiatives that want to promote cassava and look at us as the best example to promote cassava because of what and how we’re doing it.”

“We are tapping into all these markets that are readily available to consume all this cassava flour. CAVA has helped us establish the profitability of the machine and linked us to all these markets that we have to keep happy by ensuring timely provision of the product.” We have to maximize our opportunities using the Flash dryer. It is seasonal. Come rain or shine, it runs. Out-growers are awed by the technology and amazed by the fact that it dries cassava within seconds rather than what they are used to of hours and hours, days, and sometimes weeks of drying.

Innovations fostering the business / operations

Ivan states that the company is benefitting from other partner programmes secured by new partnerships formed. He attributes this exposure to linkages created by CAVA. “We have a partnership with GOAL Uganda and this has broadened our reach to other districts like Agago.

We also have a partnership with the Ministry of Science, Technology and Innovation that has given us a grant. This has enabled us acquire a new technology like the automated press and is supporting us to secure certification from UNBS. We also have a partnership in progress with GIZ. All these, we believe are avenues that are pushing us further and further to achieve our goal.”

Ivan also mentions that the factory has embraced use of ICTs to digitize the relevant information needed to boost business. “We are in the era of technology and we realize that to be successful, we have to move in that line. And so, we formed a partnership with ThinVoid, an IT company that is helping us design a farmer identification App to enable us track the duration of farmer gardens, and monitor them up to harvest.

Through new innovations, we are pushing to have as many farmers as we can. The target is 10,000 but we are currently working with 1000 that have been contracted to supply FCR to sustain factory operations on a daily basis”

Ivan is one of the youth highly recognized in cassava production and processing in Northern Uganda and has ventured into programs to support fellow youth to access clean planting material at a subsidized fee in order to sustain production for not only the factory but also ensure these have an assured income and food at home. He is a champion of the youth in agribusiness initiative that has seen 4,710 youth in the region, benefit in the cassava business.

“All these efforts are geared towards ensuring consistency in root supply. The Flash Dryer is sky rocketing processing of fresh cassava tubers into HQCF. It guarantees constant processing of fresh tubers into quality flour, irrespective of the weather burdens. We no longer rely on sunshine to guarantee output,” says Ivan.

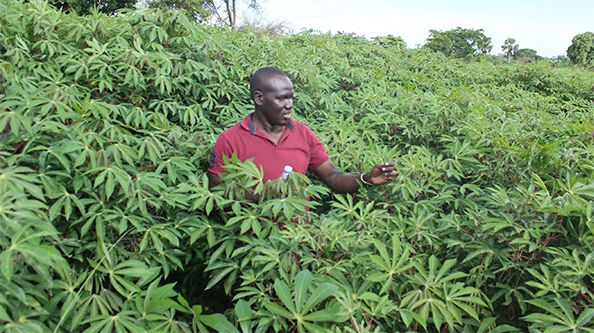

Mr. Okori in his quality cassava garden from which farmers in the region have readily accessed the material for multiplication so as to sustain fresh root supply to the factory.

Okori endorses investment in the technology

As a pioneer in the flash drying technology, Ivan encourages more investors to acquire the technology.

“It’s been a long journey. We have travelled it with tears, smiles and uncertainty along the way but here we were, standing strong amidst it all. If we did it, you too can do it, so yes, get the machine. We have set the pace and there are many lessons you can learn from our experiences, and we are readily available for any inquiries. Do a lot of market research, be creative and also be very patient with this investment. It is a long-term plan that comes with a lot of patience.

I highly recommend the technology to other processors. However, I advise that due to raw material concerns, they should be at arrange of about 150km from one another.

I also encourage fellow SMEs and farmers to plant more cassava because we are ready to consume it, work with them, ready to train them on the production and processing innovations and share our thoughts about cassava and create a market for it. Work with them and the future of cassava to our community.”

ICTs for Nutrition, Agriculture, and Time Use: Can we do better than 24-hour recall by using “innovative methods” of nutrition data collection?

In the over fifty years in which explicit efforts have been made to improve nutrition, there have been countless achievements in global understanding of the causes and consequences of malnutrition, and the actions required to change outcomes for women and children. In these same fifty years, technological advances have changed the modern world. We communicate with friends and family everywhere instantaneously on hand-held devices, and track our location, heart rate, and calories burned real-time. The confluence of smartphones with high resolution cameras and widespread access to social media outlets have made first-person photography ubiquitous.

Limitations of traditional methods. However, in this time, the methods to evaluate nutrition and key drivers of nutrition status, such as women’s time use patterns, have changed relatively little. The most widely used method for collecting data on diet quality and women’s time use is the 24-hour recall. Errors and biases introduced by the methodology are known to compromise data quality and pose a challenge to nutrition research. Direct observation, which is the gold standard, is resource intensive, imposes a serious burden on the participant, and likely influences their behavior. It is impractical for the purposes of programmatic evaluation.

Research aims and methods. The objective of the IMMANA-funded[1] ‘Using Information Communication Technologies (ICTs) to understand the relationships between labour- saving agricultural innovations, women’s time use and maternal and child nutrition outcomes’ study is to develop, validate and apply innovative methods to more accurately measure women’s time allocation and maternal and infant dietary diversity in rural Uganda. A multi-disciplinary team from the London School of Hygiene and Tropical Medicine, the Natural Resources Institute (NRI) of the University of Greenwich, and the Africa Innovations Institute (AfrII) set out in eastern Uganda to evaluate new tools and methods to capture maternal and child diet diversity and maternal time use data.

Can you collect nutrition and time use data as reliably (or more reliably) using a wearable camera, GPS logger, and automated interactive voice response (IVR) calls every 4 hours (asking about activities and diet) compared to other methods, and in a more cost-effective and less invasive manner? Over two hundred mothers are participating in a 5-day intensive study, including one 15-hour observation day, one 24-hour diet and time use recall, and two days of “innovative methods”. Dietary diversity scores for mothers and children, and calculations of women’s time allocation across key categories using the ICTs will be validated against results from direct observation, in comparison to the same validation for 24-hour recalls versus direct observation. The feasibility and acceptability of the method will also be assessed.

Early lessons learnt. The ICTs are easily available, inexpensive, and already being used for research in high income country contexts. However, devising a method for rural women with low education and literacy, limited access to electricity, limited exposure to TV or mobile phones, etc. to use photos on a tablet to recall their day posed some unexpected challenges, requiring many iterations of the protocol. It was difficult, for example, for some mothers to orient to a first-person perspective of the photos from their wearable camera – that is, to conceptualize where they were relative to the objects, people, and places in the photos. It was also challenging to devise a method that was both effective and rapid, that struck the right balance between enumerator-driven verses participant-driven interpretation of the photos, and to get enumerators and participants to see the photos as a series of activities rather than discrete snapshots.

Next steps. Conclusions from recent studies of the evidence for the role of maternal time allocation on maternal and child nutrition are limited and mixed, in part due to methodological limitations. A viable alternative to recall methods for diet and time use data collection in rural LICs has the potential to be a game-changer for the field of nutrition, and in particular the field of nutrition-sensitive agriculture. We need high quality impact evaluation data to know what works to improve nutrition. With better evidence provided by shrewd deployment of cost-efficient “innovative methods” – with a lower burden on participants and enumerators than traditional methods – we can design better and more cost-effective interventions to improve nutrition outcomes for women and children globally. The team is wrapping up data collection in early 2018; preliminary results are expected by the end of the year.

Supplementary materials:

- [INATU-pic1] Mother wearing the wearable camera and receiving her first automated IVR call while working in the sugarcane field. Key objectives of pilot testing were to rapidly assess the feasibility and acceptability of the suite of innovative tools.

- [INATU-pic2] IMMANA enumerators “code” wearable camera data before heading to the field the review the photos with mother participants.

- [INATU-pic3] This mother uses photos from her previous day (with the wearable camera) on a tablet to help her remember her activities and foods she and her child ate.

[1] Innovative Methods and Metrics for Agriculture and Nutrition Actions (IMMANA) (http://immana.lcirah.ac.uk/) is a research initiative funded by the UK Department for International Development (DFID) and coordinated by the Leverhulme Centre for Integrative Research on Agriculture and Health (LCIRAH). IMMANA aims to accelerate the development of a robust scientific evidence base needed to guide changes in global agriculture and food systems to feed the world’s population in a way that is both healthy and sustainable.

Written by Andrea L. Spray, World Bank Nutrition Consultant and PhD Candidate at LSHTM, with Gwen Varley[1], Jan Priebe1, Joweria Nambooze[2], Elaine Ferguson[3], and Kate Wellard1

[1] Natural Resources Institute (NRI), University of Greenwich (https://www.nri.org/news/2017/innovative-nri-projects-measure-up-tools-for-improved-nutrition)

[2] Africa Innovations Institute (AfrII) (https://www.afrii.org/)

[3] London School of Hygiene & Tropical Medicine (LSHTM) (https://www.lshtm.ac.uk/)

A Youth’s Dreams Come To Life Thanks To The Opportunities Created By The Flash Dryers

Sarah Adong is 24 years old and a single mother with three children. Currently, she works as a peeler at Adyaka Wholesalers Limited, a cassava flash dryer factory in Apac district. In a day, she earns between 4000 to 5000 Uganda shillings. The factory employs various laborers including 10 women peelers for its day to day operations. “The life changing moment of my life was when I was taken on for this job at the cassava factory. I know my future is brighter now, for I am able to make money.” With this employment, Adong is assured of a daily meal for her and the children. But being young, thrilled at her first job and seeming inexperienced with handling money, Adong has a plan. “I intend to join a community generating income program to guide how I will spend my earnings. I now have responsibilities around food supplies and school fees for my children. And for safety purposes, I also have to save up some of my earnings for emergencies that could arise.”

Sarah Adong is 24 years old and a single mother with three children. Currently, she works as a peeler at Adyaka Wholesalers Limited, a cassava flash dryer factory in Apac district. In a day, she earns between 4000 to 5000 Uganda shillings. The factory employs various laborers including 10 women peelers for its day to day operations. “The life changing moment of my life was when I was taken on for this job at the cassava factory. I know my future is brighter now, for I am able to make money.” With this employment, Adong is assured of a daily meal for her and the children. But being young, thrilled at her first job and seeming inexperienced with handling money, Adong has a plan. “I intend to join a community generating income program to guide how I will spend my earnings. I now have responsibilities around food supplies and school fees for my children. And for safety purposes, I also have to save up some of my earnings for emergencies that could arise.”

She feels rather relieved that she is not yet tied down by demands for school dues. Her eldest child is in primary one, the second is in baby class and the youngest is still at the breast. “Fees is not yet as demanding because my children are still quite young. This gives me the opportunity to plan accordingly and save up as much as I can for their tuition and scholastic materials.” Says a smiling Adong. Aside from her responsibilities, Adong has even much bigger plans. “My dream is to one day own a business of my own and become an influential woman in society. This clever idea (being in a group) provides me with hope.” She says.

Born in Lira district, Adong is the second last of 6 siblings. Due to poverty and its related challenges, she was forced to leave their birth home 3 years ago in search of a job to live better. That is how she ended up in Apac district. Her life in Apac was also however challenging, and being a single mother with no assured income to survive on, her dreams seemed hopeless for sometime. But now, employed and earning, many of her dreams are coming to life including that of looking after her younger sister. “Growing up as orphans was very challenging especially for me and my two sisters. We were under our elder step brothers and life was not smooth. When I got to 21, I moved out of home to try and make a living. It was however hard leaving my little sister (our last born) behind. Now that I have a job, I plan to bring her here and help her get a job as well.” She adds “I know that by the end of the year, I will have saved up enough money to and go get my little sister and give her hope in the future she seems to have given up on.”

Adong’s story is one relatable to many youths in Uganda out there that are faced with life’s challenges and are looking for a better life through employment. For Adong, her dreams are coming to life, thanks to the Cassava Adding Value for Africa Phase Two (CAVA II) Project that has extended such opportunities to the youth and other people through beneficial community projects. The CAVA II Project facilitated the successful installation of the two cassava factories of Windwood Millers Limited and Adyaka Wholesalers Limited in Lira and Apac districts respectively. Each factory needs about 16 tons of Fresh Cassava Root (FCR) per shift which is dried into 4 tons of High Quality Cassava Flour (HQCF) per shift.

CAVA II is implemented in five African Countries of Nigeria, Ghana, Malawi, Tanzania and Uganda with support from the Bill and Melinda Gates Foundation (BMGF) through the Natural Resources Institute, University of Greenwich, (NRI). Specifically, in Uganda, CAVA II aims to create by 2019 an annual demand for 69,030 tons of FCR from smallholder farmers and incomes from sale of fresh roots and processing by smallholders who will generate at least USD 4.5 Million/ annum for rural communities.

CSS Project supported farmer gets accolade for best Cassava Seed Entrepreneur

Successful cassava farmer and beneficiary of the Cassava Seed Systems Project (CSS), Mr. Akuttu Augustine recently won an award for “Best Cassava Seed Entrepreneur 2013-2017” under the Cassava Seed Systems Project. Mr. Akutu, a resident of Amuria district in Eastern Uganda was also awarded a certificate of inspection on fulfilling the quality and plant health standards for cassava planting materials. The certificate qualifies him to supply certified cassava stems for planting during the year 2017. He got the two credits in June 2017 this year.

Mr. Akuttu owns over 300 acres of cassava spread out in parts of Amuria, Soroti and Serere districts. Last year, in 2016, he made sales of 170 Million Uganda Shillings from 3500 bags of cuttings sold. This year, he supplied 1275 bags of stems and earned 60 Million Uganda Shillings. He has also been contracted by the Government’s National Agricultural Advisory Services (NAADS) to supply cassava cuttings to neighboring districts including Abim.

His proceeds have been used to among other things, buy more land to expand acreage to grow more cassava, set up new constructions at home and a commercial building in Soroti town.

Also recognized with a similar certificate is Mr. Sam Opio, another successful Cassava Seed Entrepreneur and owner of Adyaka Farm in Apac district -Northern Uganda. Mr. Opio owns over 150 acres of cassava and is still expanding his acreage with aim to further boost his cassava business but also to ensure sustainable root supply for his cassava Flash drying factory of Adyaka Wholesalers Limited, also located in Apac district.

As a certified seed entrepreneur, Mr. Opio has been contracted to supply cuttings to the Government’s Operation Wealth Creation (OWC) this year, 2017. Also, in 2016, last year he supplied cuttings to OWC and earned 200 Million Uganda Shillings.

The Cassava Seed Systems Project (CSS) aims to catalyze the establishment of a functional cassava seed system to effectively regulate the production and dissemination of quality cassava planting materials in Uganda so as to improve food security and livelihoods of the small holder farmer through timely and cost effective access to disease free cassava planting materials.

The key implementers of the project are the Africa Innovations Institute (AfrII), National Crops Resources Research Institute (NaCRRI), CHAIN Uganda, BioCrops and the Ministry of Agriculture Animal Industry and Fisheries (MAAIF).

Cassava farmer expands farming business with CAVA II trainings and Farmer-to-Farmer technical assistance

Christine Nalubinga is a farmer and member of NADIFA in Nakasongola. She is a housewife, but for the last 10 years has engaged in farming with her husband. She began cassava farming, despite having no prior training in cassava production.

Christine and her husband have 13 Children. She is 45 and he is 48 years old. The couple had for a long time been planting cassava the old fashioned way until in 2013 when CAVA intervened. Their efforts then were not of much benefit given the poor harvests obtained from their small gardens. Years later, their farming business has expanded and the couple has bought some cows, which they use during planting. Her cassava business continues to grow at the new cassava opportunities opening up greatly.

“We harvest about 150 bags of stems and sell each bag at 35,000 Uganda shillings giving us an earning of about 4 million Uganda shillings in just a month. We also earn a lot from processing.This is cassava money that has greatly improved our household status”-Christine Nalubinga. The couple today owns 3 and a half acres of cassava of the NASE 14 and NAROCASS 1 varieties, and plans to expand their acreage with an additional 1 acre on which to plant more cassava.

Christine narrates how it all came about. ‘It so happened that one day we were among the many farmers mobilized for a training on cassava production and it is from then that our lives changed. We have since had access to quality seed of the NASE 14 and NAROCASS 1 varieties.’ Christine says.

The couple was however by then not part of the Nakasongola District Farmers Association (NADIFA) group until after seeing the benefits of belonging to a group after a training they attended. ‘We were trained on good agronomic practices and management of the cassava crop and after the training my husband and I registered to be part of NADIFA’ Christine adds.

Since joining the NADIFA group, the couple has seen tremendous changes in their livelihoods. They are food secure, able to provide an education for their children, engage in farming of other crops and also rearing livestock. The couple has also constructed a house and purchased more land to expand their farming business.

CAVA II Uganda has been greatly influential in offering trainings and imparting knowledge and skills to the farmers in not only good agronomic practices but also processing of HQCF.

In a month, the group processes about 70 tons of FCR with the breweries being their largest end user market. Other markets include the local bakeries and home consumption.

Reaping big from cassava farming

Mr. Okiror Gilbert a Cassava Seed Entrepreneur (CSE) from Koloin in Ngora District, with his bags of packaged clean cassava stem cuttings he intends to sell to fellow farmers to boost multiplication of clean cassava seed.

Mr. Okiror recently made sales on cassava cuttings / stems worth about 2.5 million Uganda Shillings from clean planting materials of the NaSE 19 variety that he accessed from AfrII through the Cassava Seed Systems Project in collaboration with the CAVA II Project, both implemented by AfrII.

Through the two projects, farmers like Mr. Okiror have readily accessed certified and high yielding disease tolerant varieties of NaROCASS I, NaSE 14, and NaSE 19 of cassava seed for planting, to increase yield production.

He commends AfrII for enabling him access clean seed for multiplication and also for availing him skills and Knowledge in good agronomic practices including practicing row planting of the cassava seed, and timely weeding among others to boost high yield production.

In the photos:AfrII Zonal Manager, Mr. Anthony Ijala (In stripped shirt with black jacket),CAVA II Uganda Country Manager-Mr Francis Alacho (white shirt) and Mr. Okiror Gilbert, a CSE.

Cassava farming saves farmers from trekking miles to access water

The Awuco family, 77-year-old Victor and 57-year-old Phoebe Awuco, cassava farmers of Alito sub county in Kole District, Northern Uganda are enjoying the benefits of investing in value addition of the cassava crop and have recently constructed an underground water tank from earnings they saved from cassava production. The couple has been travelling a distance of 2 Kilo meters to fetch / access water for use during the processing of cassava.

They delightfully shared their moment of bliss of their new innovation “We spent nearly 1 million Uganda Shillings of our savings from cassava to construct this water tank and we are content with this new development for we no longer have to walk many kilo meters to get water with which to use to wash the fresh cassava roots, as well as rinse and soak the roots before processing them to obtain HQCC and flour. The water for all this is now right in our back yard” (Both smile)

Mr. Awuco then adds “It has not been a smooth road but we have managed, my wife is very supportive in each step of the way”

Blessed with 3 children of their own and 8 grandchildren, the Awuco family is greatly benefitting from farming cassava and have also realized the benefits of conducting business in cassava processing following the successes that have come along with this.

The couple’s first achievement from cassava farming and processing was a motorcycle they purchased back in 2014. The motorcycle has since eased their transportation challenges to easily access the market where they sell their cassava flour, and also purchase other household requirements like food stuffs.

The Awuco’s have also been able to finance the education of their grandchildren to as far as university level through cassava farming “Cassava has greatly improved our household livelihoods. We are able to buy food, cater for medical expenses and also take our grandchildren to school. Our eldest grandson has been admitted to Kyambogo University this year 2016 to study electrical engineering. This is great for us as a family” Mr. Awuco recounts.

The couple has been farming cassava for 3 years and in May 2016 this season, they set up a 1acre demonstration garden of the Narocass1 cassava seed variety. They have been growing the Nase14 cassava variety since 2013.

The couple is also a member of Alito Cassava Farmer Growers Association and Community Processing Group (CPG) that is supported by AfrII under the CAVA II project. The Alito cassava processing site was commissioned in 2014 by the Africa Innovations Institute (AfrII) at the commencement of the second phase of the Cassava: Adding Value for Africa (CAVA II) project.

The Awuco’s acknowledged CAVA II Uganda for the support extended ‘We are grateful to CAVA II for their contribution and also appreciate the work they are extending to us at the community through the CAVA II project in as far as providing us access to new technologies aimed to promote cassava production”

The Cassava: Adding Value for Africa Phase Two (CAVA II) Project supports value addition in cassava and commercialization of cassava in Africa. In Uganda, the CAVA II project has successfully developed value chains for High Quality Cassava Flour (HQCF) by supporting investors to establish HQCF processing sites in Eastern, Northern and Central Uganda. The project beneficiaries include among others, small holder farmers, Small and Medium Enterprises and selected actors working on cassava value chains.

CAVA II’s purpose is to increase the incomes of 23,010 Small Holder Framers (SHFs) and community processors through participation in profitable and sustainable value added cassava chains in Uganda and is being implemented in 18 districts of Pallisa, Kibuku, Budaka, Bukedea, Kumi, Soroti, Ngora, Serere, Dokolo, Nakaseke, Nakasongola, Lira, Apac, Otuke, Oyam, Kole and Alebtong.

The project is also being implemented in 4 other African countries of Nigeria, Ghana, Tanzania, and Malawi.